3D Printing Services

PolyJet 3D Printing

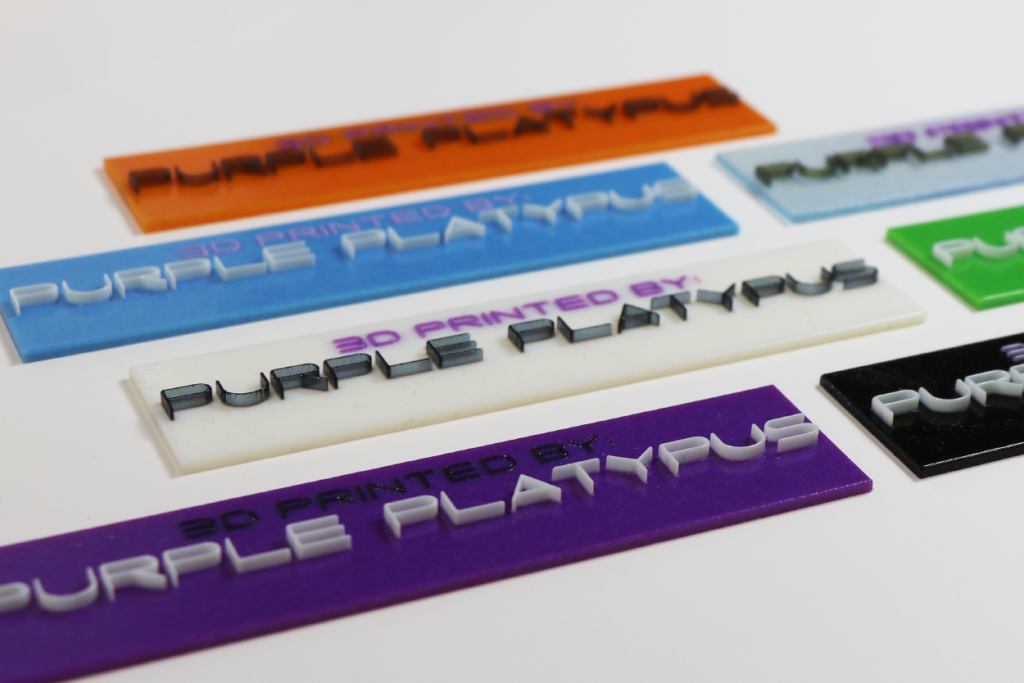

FULL-COLOR, PANTONE VALIDATED PRINTS

With 650,000+ color combinations to choose from and multi-material capabilities, Purple Porcupine can help you create prototypes that look, feel, and operate like finished products.

Why PolyJet?

PolyJet technology offers exceptional detail, surface smoothness, and high precision. With over 650,000+ color options, including Pantone Validated Colors, and multi-material capabilities, you can accurately create prototypes that convey final-product aesthetics.

Whether your part has intricate shapes or delicate features, PolyJet technology can leverage complex geometries and make your ideas come to life.

Request A Quote

Applications

Design smooth, detailed prototypes and incorporate the widest variety of colors and materials into a single model for unbeatable efficiency.

PolyJet can also enable you to create accurate molds for cast urethane or injection molding. The ability to use a variety of durometers within a single print means that you can create manufacturing tools to streamline your production process.

Digital anatomy materials allow our team to create biomechanically correct parts. Whether used for surgeon training or to perform testing during medical device development, models provide unmatched clinical versatility, mimicking both appearance and response of human tissue.

Materials

Digital materials offer a wide range of flexibility, from Shore A 27 to Shore A 95, and over 650,000 color options.

Rigid opaque materials offer brilliant color options for unprecedented design freedom and can be combined with rubber-like materials to create a wide variety of parts.

Simulated polypropylene replicates the appearance and functionality of polypropylene, like appearance, flexibility, strength, and toughness.

High temperature materials offer exceptional dimensional stability for thermal functional testing.

Biomechanically accurate materials allow you to create models that mimic human cardiac and vascular anatomy.

Transparent materials feature optical clarity and can be combined with color materials for stunning transparent shades.

Rubber-like materials offer various levels of elastomer characteristics and can be combined with rigid materials for a variety of Shore A values, from Shore A 27 to Shore A 95.

Digital ABS Plus simulates ABS plastics by combining strength with high temperature resistance, leading to enhanced dimensional stability for thin-walled parts.

Biocompatible materials feature high dimensional stability and colorless transparency. The material has five medical approvals including cytotoxicity, genotoxicity, delayed type hypersensitivity, irritation and USP plastic Class VI.

How It Works

Contact Our Team

Reach out to our team through the above form or upload your 3D part file through our secure online upload system.

Finalize Your Design

Whether you’re using our CAD design engineering services or have a completed 3D design, our team will make sure your part will print error-free.

Print Your Part

With an average lead time of 2.6 days, our team will print, clean, and ship your part quickly and effectively, expediting your time-to-market.

The Process

With PolyJet technology, a jetting head slides back and forth along the X-axis, similar to a line printer, depositing a single super-thin layer of photopolymer onto the build tray.

Immediately after building each layer, UV bulbs alongside the jetting bridge emit UV light, immediately curing and hardening each layer. This step eliminates the additional post curing required by other technologies.

To learn more about PolyJet technology and how you can leverage it, contact our team.

At Purple Porcupine, you can depend on our 3D printing & rapid prototyping service to be exceptional, and our 3D printed models to hold tight tolerances with premium finishes. We use only the best of rapid prototyping technologies that will provide optimal solutions to change the way you design and create products.

ITAR Registered · 949.474.7222 · partsfast@purpleporcupine.com · Start Your Project Today

Rapid Prototyping. Today.

No matter what industry you come from, rapid prototyping is changing the way business is done. Through highly accurate, cost-effective and time-efficient processes, 3D rapid prototypes can be created in mere days.